The UK’s Ministry of Defence (MOD) plans to 3D print parts for weapons and other military equipment on demand, under an experimental new £5 million programme called “Project Tampa”.

MOD aims to be able to share print files over secure defence networks then get parts made swiftly using additive manufacturing (AM), or 3D printing, to tackle “excessive lead times for defence inventory”.

Project Tampa will also help it print obsolete parts to “improve platform availability” MOD said.

The project launch comes a year after the US Department of Defense (DOD) established its own comprehensive additive manufacturing strategy. The strategy will give DOD “unprecedented supply chain agility”, said Robert Gold, Director of the Technology and Manufacturing Industrial Base (TMIB) Office in 2021.

DOD’s strategy notes that “where parts cannot be acquired and data is not available, reverse engineering and AM part production is an approach to support legacy systems and impact readiness” but emphasises that “there are significant challenges and concerns regarding intellectual property rights and what opportunities are open with respect to reverse engineering end item parts for limited and rapid production…”

MOD 3D printing plans: Not a lot of money involved…

MOD is now inviting defence contractors – which already have equipment/platform support contracts in place to provide MOD with NSN (NATO stock number) military spare parts – to join a new procurement framework that was first teased on April 4, 2022. Once they are part of the procurement framework, they will be able to bid for “limited innovation funding to conduct ‘spiral’ development tasks” under the seven-year framework.

MOD said in a September 16 contract notice that it wants the programme to start “accelerating the maturity of Additive Manufacturing technology to better exploit the technology within the end-to-end support chain, deliver a more agile response to demand for parts, and begin to generate the inherent efficiencies that this technology promises” but it is putting a highly limited pot of money into the Project Tampa framework.

Follow The Stack on LinkedIn

Whilst the procurement framework will no doubt be welcomed by the 3D printing industry, the £5 million funding over seven years is just 0.02% of MOD’s annual equipment spend, or the equivalent of 200 81mm mortar rounds. The contract notice has MOD acknowledging “that the funding available from the Authority needs to be underpinned by a level of investment from suppliers in order to realise the advantages of this technology.”

Project Tampa will include four “spirals”.

The first will produce a non-safety critical metallic NSN, or military part, with MOD adding that this “will be followed by a series of further spirals that will seek to incrementally address increasing degrees of complexity.”

Spiral 2 will involve a safety-critical metallic NSN, “produced in the Industrial base, certified by the producer (OEM or under licence)”; Spiral 3 will involve 3D printing a “non-safety critical metallic (or polymer) NSN, produced in a location remote from the Industrial base, certified by the producer”; Spiral 4a “safety critical metallic (or polymer) NSN, produced in a location remote from the industrial base, certified by the producer; and Spiral 4b cover the 3D printing of a “non-safety critical metallic (or polymer) NSN, produced in a location remote from the Industrial base, certified by the producer and where access to Design Rights is required.

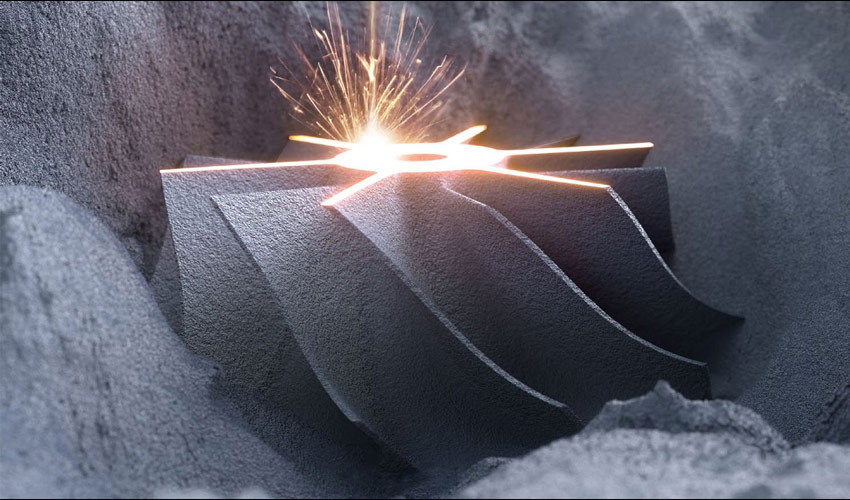

The quality and robustness of 3D printed metal parts continue to be a challenge. The laser powder bed fusion (LPBF) approach used in much AM work lets engineers fabricate complex metal geometries, but the heat generated by the high-power laser beams can often result in pores being formed that weaken components.

As DOD noted in its own 3D printing strategy: “The range of complex geometries, novel materials, and unique microstructures enabled by AM can challenge some of the conventional approaches to nondestructive inspection (NDI). Investment in standardization and development of NDI validation will be a continued priority for DoD to advance the state of the art in inspection techniques to match AM requirements.”